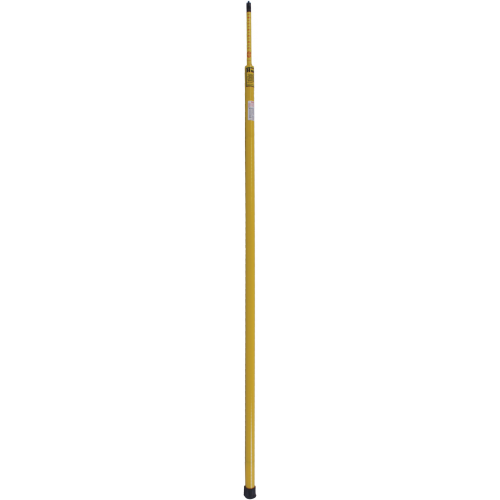

SMOOTHER SURFACE

Conventional fiberglass construction uses a woven mat. This creates pockets and voids where dirt and moisture can collect. Our unique non-woven fiberglass is unidirectional which creates a smoother surface. The BLUE STRIPE® Fiberglass Hot Sticks have a lineman friendly grip, stay cleaner longer and are easier to clean and meet standards.

EPOXY RESIN

The BLUE STRIPE® Fiberglass Hot Stick line uses Epoxy resin which is the most water resistant, durable and longest lasting resin available and has superior electrical properties. Our sticks have a very high resistance to failure due to water absorption or delamination.

HIGH PERFORMANCE CLOSED CELL FOAM

Foam filled tip sections add a measure of safety by sealing the interior which prevents water from entering.

Our superior Closed Cell Foam construction is durable and long lasting; extending the safety margin and strength of the stick.

EASY TIP LOCK REPLACEMENT (patent pending)

Our patent pending Easy Tip Lock Replacement feature saves time and money. Buttons can be replaced without sacrificing the entire tip section. The repair is easy enough to be done in the field so sticks stay on the job longer and repair costs go down.  Bucket operable models not available with Tip Lock feature.

Bucket operable models not available with Tip Lock feature.

BLUE STRIPE® PATENTED ALIGNMENT FEATURE

The most revolutionary design change to hot sticks since fiberglass is our patented BLUE STRIPE® alignment feature. ![]() Extending even our 50 footer is easy with this ingenious button alignment feature. These products are patent protected under Patent number 6,875,917 and other patents pending.

Extending even our 50 footer is easy with this ingenious button alignment feature. These products are patent protected under Patent number 6,875,917 and other patents pending.

CNC MACHINED BUTTONS & SPLINE ENDS

The most vulnerable parts of any stick are the spring loaded plastic buttons and the spline ends. Molded and cast parts can be less expensive to produce but are often less durable. We machine each button and aluminum spline end out of solid material.

WARNING: Cancer and Reproductive Harm – www.P65Warnings.ca.gov